Product Stewardship

Our Group Approach

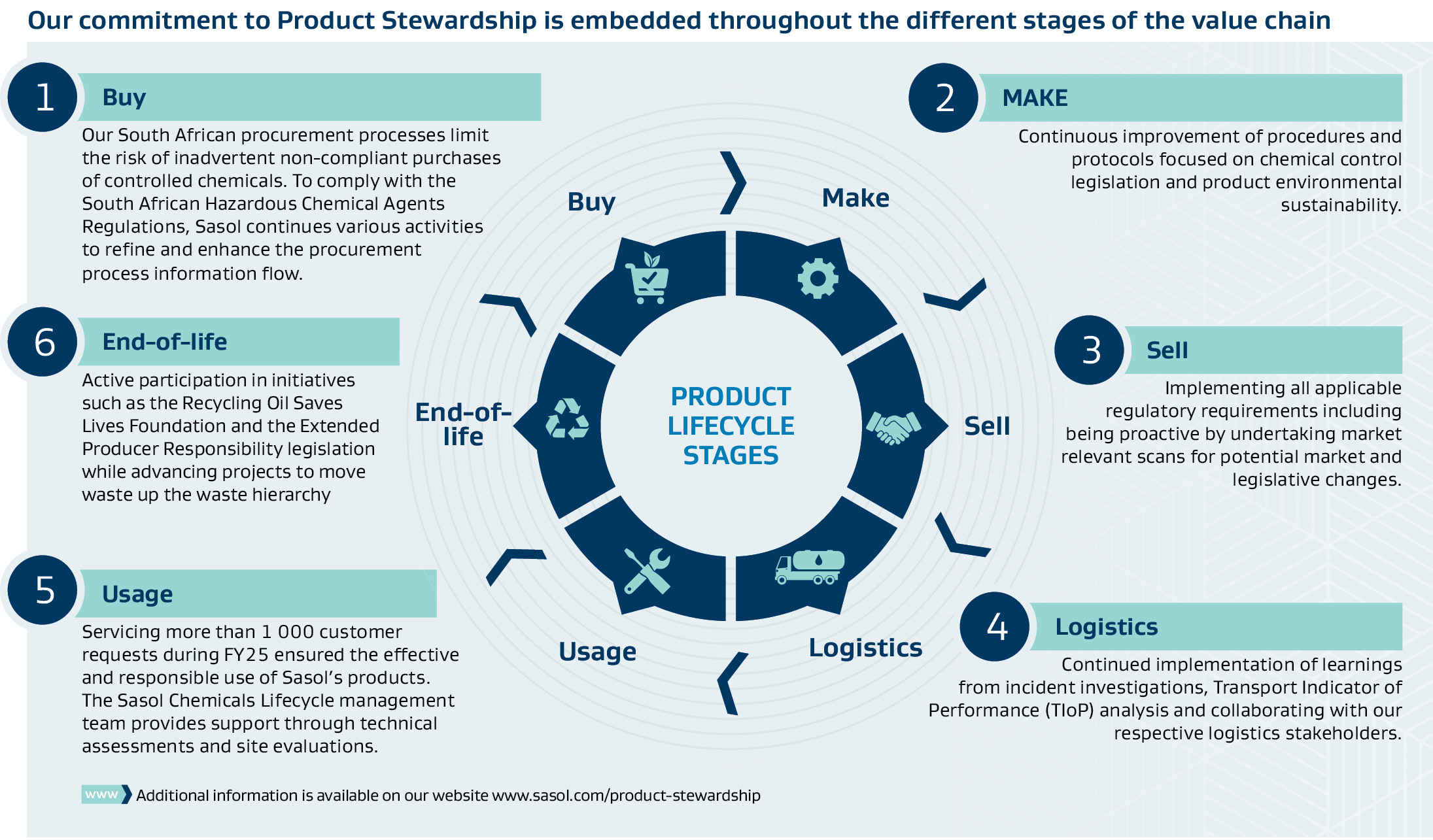

Through our well-established product stewardship approach, we aim to ensure safe chemicals management throughout a product’s lifecycle, while also ensuring that the chemistry contributes to society and benefits the environment. This is addressed by:

- Establishing trust in the Sasol brand

We do so by consistently fulfilling our commitment to product stewardship across the entire value chain.This not only mitigates product risk but also minimises any liability; - Maintaining a team of global technical experts

Our team possesses a deep understanding of product hazards, risks and regulatory requirements. They actively drive continuous improvement to prevent product-related incidents and minimise health and environmental exposure; and - Engaging with partners and stakeholders

We conscientiously collaborate with our partners and stakeholders along the value chain, promoting safe and responsible practices related to storage, use, conversion and end-of- life management of our products.

Our Commitment

Sasol is a committed Responsible Care® signatory. Through our well-established product stewardship approach we endeavor to prevent any potential adverse impact on life and the environment associated with the chemicals we use and the products we manufacture, including minimising impacts throughout the entire product life cycle.

To fulfill safe chemicals management as entrenched in our Group Safety, Health and Environment (SHE) Policy, we commit to the following key focus areas:

Sasol Limited Board

Broad Stakeholder Collaboration

Sasol acknowledges that product stewardship is a shared responsibility of all parties involved in a product’s life cycle. Active engagement and collaboration with our stakeholders, including suppliers and customers, on safe hazardous product management is a key focus.

Sasol acknowledges that product stewardship is a shared responsibility of all parties involved in a product’s life cycle. Active engagement and collaboration with our stakeholders, including suppliers and customers, on safe hazardous product management is a key focus.

Advancing Global Chemical Safety: Sasol’s Commitment to International Cooperation

Since 2023, Sasol has been a proud advocate for chemical safety and security through its active support of the Organisation for the Prohibition of Chemical Weapons (OPCW)) Capacity Building Programme. In partnership with the South African Department of

Trade, Industry and Competition, Sasol hosted four candidates for three weeks, offering them practical industry experience.

The OPCW is committed to the global eradication of chemical weapons and preventing their re-emergence by enforcing the Chemical Weapons Convention. A key component of this mission is the beneficial relationship with the chemical industry, exemplified by the Industry Candidate Training Program. This program fosters cooperation by training industry professionals in compliance, safety, and security measures related to chemicals.

Sasol’s collaboration with the OPCW ensures that industry partners are well-equipped to support the OPCW's verification regime and contribute to a safer, chemical weapon-free world. Over the past two years, Sasol has supported these four candidates, focusing their research on:

- Endocrine disruptor classification processes

- Studies on the phase-out of polyfluoroalkyl substances (PFAS) in firefighting foam

- Security aspects during the life cycle of Sasol products

- Green hydrogen safety

By engaging in these critical areas of international cooperation, Sasol not only enhances its own safety and security protocols but also contributes significantly to global chemical safety and security initiatives. This commitment underscores Sasol’s dedication to fostering a safer and more sustainable world.

Effective external communication on Sasol product hazards

Potential hazards of all Sasol’s products are communicated to stakeholders via appropriately detailed hazard communication documents

Potential hazards of all Sasol’s products are communicated to stakeholders via appropriately detailed hazard communication documents, including Safety Data Sheets aligned with the Globally Harmonized System of Classification and Labelling, Regulatory Information Sheets, engagements and training as necessary.

Risk-based approach to chemicals management

Within Sasol, various governance measures and practices are in place to mitigate potential risks across the life cycle of our products, with risk assessments performed for all products as informed by different national and regional requirements. Critical to the risk assessment process is input on the inherent substance hazard potential provided through the hazardous product classification applying the Global Harmonized System with applicable jurisdictional chemical control regulatory requirements.

Within Sasol, various governance measures and practices are in place to mitigate potential risks across the life cycle of our products, with risk assessments performed for all products as informed by different national and regional requirements. Critical to the risk assessment process is input on the inherent substance hazard potential provided through the hazardous product classification applying the Global Harmonized System with applicable jurisdictional chemical control regulatory requirements.

Life Cycle Assessment (LCA)

LCA is a standardized method for analyzing the potential environmental impacts of products throughout their entire lifecycle, as described in ISO 14040 and ISO 14044.

When the analyzed impact category is limited to climate impact, it is referred to as a Product Carbon Footprint (PCF), with ISO 14067 applying. Given the current focus on reducing contributions to climate change, we are concentrating on attaining greater insight of the carbon footprint of our products. This includes all greenhouse gases, whose impacts contribute to the overall result as carbon dioxide equivalents. In addition to the corresponding ISO standard (ISO 14067), we also refer to the PCF Guideline from “Together for Sustainability,” which provides recommendations specifically for PCF creation by the chemical industry.

When Sasol began to engage in PCF calculations, it was within the context of specific projects covering a few products at a time. Customer inquiries related to this information have been growing steadily and continue to do so. Our goal now is to have most of our product portfolio covered with PCF information. We are systematically covering all Sasol sites to supply our customers with PCF information as requested. We aim to update the models annually, which will be used to update datasets related to plants, suppliers, lifecycle inventories, and to analyze the impact of potential improvement measures on the PCF results. Sasol is progressing well towards being able to provide PCF information for more than 90% of our production volume.

Advancing Safe Management of Hazardous Products through a Risk-Based Approach

In alignment with Sasol’s Group Commitment to the Safe Management of Hazardous Products specifically Key Focus Area 3: Risk-Based Approach to Chemicals Management, Sasol has robust governance measures to proactively manage potential risks across the entire life cycle of our products.

At Sasol, risk assessments are conducted for all products, guided by applicable national and regional regulatory frameworks. A cornerstone of this process is the evaluation of inherent substance hazards, which is informed by the classification of hazardous products in accordance with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), as well as jurisdiction specific chemical control regulations.

Importantly, 100% of Sasol’s product portfolio is classified and labelled in full compliance with the GHS, ensuring consistency, transparency, and safety in communication across global markets. This universal approach to hazard communication not only facilitates regulatory compliance across jurisdictions but also enhances the protection of human health and the environment by enabling clear, harmonized understanding of chemical hazards among workers, customers, emergency responders, and downstream users. By adopting GHS, Sasol supports safer handling, transport, and use of its products throughout the value chain.

Product development towards less hazardous formulations

When developing new products for existing or new applications, Sasol aims to minimise the hazard potential as far as reasonably possible while maintaining the desired function of the product. In most instances the hazard potential correlates directly with the intended physico-chemical properties of the products, however some may warrant minor modifications to reduce the hazard while maintaining the desired substance properties that make them useable and safer in customers’ applications.

When developing new products for existing or new applications, Sasol aims to minimise the hazard potential as far as reasonably possible while maintaining the desired function of the product. In most instances the hazard potential correlates directly with the intended physico-chemical properties of the products, however some may warrant minor modifications to reduce the hazard while maintaining the desired substance properties that make them useable and safer in customers’ applications.

Designing safe products

Our commitment to providing a safe and competitive product portfolio involves an ongoing review process. Through our global team of Sasol experts, we proactively and continuously scan regulations, screen peer-reviewed scientific research on chemical safety, and engage in product development. This enables us to anticipate any legal changes that may impact products ahead of formal regulatory adoption.

Sasol adheres to various environmental and safety standards:

- REACH Compliance: Sasol has two substances (occurring as impurities) listed on the European Union’s REACH SVHC candidate list and no products on the authorisation list.

- Montreal Protocol and Stockholm Convention: Sasol’s value chain avoids materials related to these multilateral environmental agreements.

- Basel Convention: Sasol exports spent catalysts with precious metals for recovery, reducing the need for mining and promoting a circular economy.

- International Cyanide Management Code: One Sasol product is certified under this voluntary code.

Portfolio optimisation to safer, sustainable alternatives

Sasol aims to meet the evolving needs of customers by providing products fit-for-safe and sustainable use. Although many of Sasol’s products are not classified as hazardous, or classified only for acute potential health effects e.g. irritation, we continuously review known applications of all our products to improve its SHE impact with the objective of preventing unacceptable risks to life and environment. We remain committed to innovate for safe and sustainable alternatives.

Sasol aims to meet the evolving needs of customers by providing products fit-for-safe and sustainable use. Although many of Sasol’s products are not classified as hazardous, or classified only for acute potential health effects e.g. irritation, we continuously review known applications of all our products to improve its SHE impact with the objective of preventing unacceptable risks to life and environment. We remain committed to innovate for safe and sustainable alternatives.

Designing safe products

Our commitment to providing a safe and competitive product portfolio involves an ongoing review process. Through our global team of Sasol experts, we proactively and continuously scan regulations, screen peer-reviewed scientific research on chemical safety, and engage in product development. This enables us to anticipate any legal changes that may impact products ahead of formal regulatory adoption.

Toluene free Thinners

Sasol Chemicals has introduced a safer, internally sourced hydrocarbon to replace toluene in our thinner solvent formulations. This innovation enhances health and environmental safety, supports sustainability, and reduces reliance on external raw materials - delivering smarter, more responsible solutions.

Development of a Phthalate-Free Polypropylene Polymer Grade

In response to evolving product understanding and customer demand, Sasol Chemicals developed and commercialised a phthalate-free polypropylene grade. This innovation aligns with global safety standards and supports safer applications in sensitive industries.

Sasol’s International Sustainability and Carbon Certification (ISCC) PLUS certifications

The ISCC PLUS certification promotes environmentally, socially and economically sustainable production. Four of our Eurasian sites (Brunsbüttel, Marl, Augusta, and Terranova) maintain ISCC PLUS certifications to enable the use of bio-based and circular feedstocks on a mass balance basis to replace fossil-based feedstocks. www More information can be found on the Sasol Chemicals extranet via the following link: Certifications.

Safe transport of products

Sasol is committed to safe and responsible distribution of our products and to proactively mitigate any potential ‘in transit’ incidents. Compliance with applicable regulatory requirements regarding transporting, handling and storage of our products, as well as prevention of incidents and responsible management of incidents, remains a minimum imperative.

Sasol is committed to safe and responsible distribution of our products and to proactively mitigate any potential ‘in transit’ incidents. Compliance with applicable regulatory requirements regarding transporting, handling and storage of our products, as well as prevention of incidents and responsible management of incidents, remains a minimum imperative.

Sasol conducts an emergency response simulation in Mbombela, Mpumalanga Province on N4

Demonstrating its commitment to safety and community protection, Sasol conducted a comprehensive Product Transportation Offsite Emergency Response Exercise in Mbombela in November 2024. This collaborative initiative, involving public and private stakeholders, tested emergency preparedness for hazardous material transport and reinforced Sasol’s world-class safety culture.

The exercise yielded key insights including highlighting strong initial response capabilities, the need for enhanced personal safety practices, and the importance of clear inter-agency communication. It also informed updates to emergency protocols, reducing operational risk and strengthening environmental and community safeguards.

This initiative is a testament to Sasol’s values in action. By continuously investing in preparedness, collaboration, and learning, we demonstrate our unwavering commitment to being a caring citizen and living our core value to Be Safe.

Through partnerships and proactive engagement, it highlights how we work with our stakeholders to embed a world-class safety culture at every touch point in the product delivery value-chain.

Strengthening logistics risk management and operational efficiency

Sasol has embedded the internationally recognised SQAS (Safety and Quality Assessment for Sustainability) framework into its logistics operations to ensure rigorous evaluation of Logistics Service Providers (LSPs) across key performance areas, including safety, environmental compliance, and corporate responsibility.

Following the transition of SQAS-AFRICA audit responsibilities to the Chemical and Allied Industries’ Association (CAIA), Sasol has strategically reallocated its internal audit resources to strengthen internal assurance capabilities. This shift enables Sasol to maintain influence over industry standards through CAIA forums, while benefiting from more independent, industry-led audits and contributing to industry upskilling through the sharing of SQAS institutional knowledge. This evolution signals Sasol’s continued commitment to operational excellence, risk mitigation, and sustainable value creation across its logistics network.

Driving road logistics safety through awareness, training, and strategic partnerships

Sasol continues to prioritize safety and collaboration in the transport of hazardous materials through targeted community and stakeholder engagement. In Mbombela, awareness roadshows and structured training sessions equipped over 300 first responders and community members with critical knowledge on hazardous goods and emergency response. These sessions have proven essential in empowering both communities and emergency personnel to respond effectively and safely to incidents involving hazardous materials. Complementing this, the 2024 Transporter Forum brought together contracted transporters under the theme “Compliance Creates Sustainability,” reinforcing Sasol’s commitment to embedding safety, regulatory compliance, and long-term resilience across its logistics operations. These initiatives reflect Sasol’s proactive approach to fostering safer communities and a more sustainable supply chain.

Accolades

Sasol won two awards at the Chemical and Allied Industries Association (CAIA) Responsible Care® 2024 awards ceremony

Responsible Care® is the global industry’s voluntary initiative to drive continuous improvement in safe chemicals management and achieve excellence in environmental, health, safety and security performance. CAIA, the local custodian of Responsible Care® in South Africa, is responsible for setting and implementing the local principles which are based on the global commitment as per the International Council of Chemical Associations.

Sasol’s unwavering commitment to Responsible Care® principles has been recognized with two prestigious CAIA awards. The company received the Responsible Care® Sustained High Performance Award – Category B, which honours chemical industry leaders demonstrating consistent adherence to Responsible Care® principles through annual KPI evaluations. Additionally, Sasol was awarded the Responsible Care® Initiative of the Year Award – Category A for its outstanding project in removing toluene from Turposol 17, significantly enhancing health, safety, and environmental performance. These accolades, highlighting the dedication and hard work of Team Sasol in setting industry benchmarks and reflecting the collective efforts of their diverse teams to deliver outstanding results consistently.

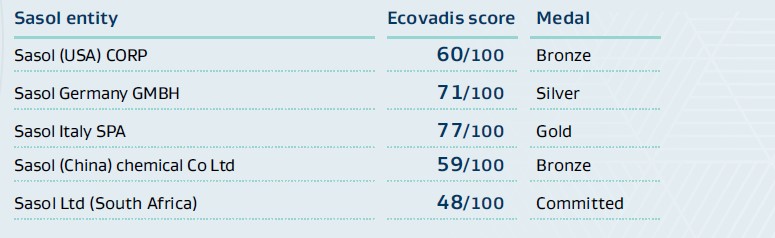

Sasol awarded three EcoVadis medals

FY25 was another successful year, with four Sasol entities receiving EcoVadis medals – demonstrating Sasol’s strong commitment to sustainability. EcoVadis is one of the largest global sustainability ratings agencies, providing a comprehensive and holistic view of a company’s sustainability performance. Its scoring methodology is constantly refined to reflect evolving sustainability standards, regulatory expectations, and industry best practices. Therefore, achieving high recognition levels has become increasingly challenging. Sasol Italy and Sasol Germany are achieving gold and silver medals.

2nd place for Sasol Germany in the VCI Nord’s Responsible Care Initiative on the topic of “safe and healthy working environment”

Sasol Germany GmbH, with locations in Hamburg, Brunsbüttel and Marl, has achieved 2nd place in the Responsible Care Initiative organised by the Verband der Chemischen Industrie Landesverband Nord e. V. (VCI Nord). The competition focused on the topic “Our commitment to a safe and healthy working environment”.

Sasol Germany participated with its “Safety and Health Days” initiative, organized at its Hamburg, Brunsbüttel and Marl locations. The “Safety and Health Days” address a wide variety of aspects from the areas of occupational safety, health protection, well-being and health promotion.

Sasol Responsible Care ® Global Charter 2025

Sasol South Africa Limited Responsible Care ®CAIA Declaration 2025

Sasol South Africa Limited Responsible Care ® Management Representative Certificate 2025

Sasol Group's commitment to safe management of Hazardous products 2023